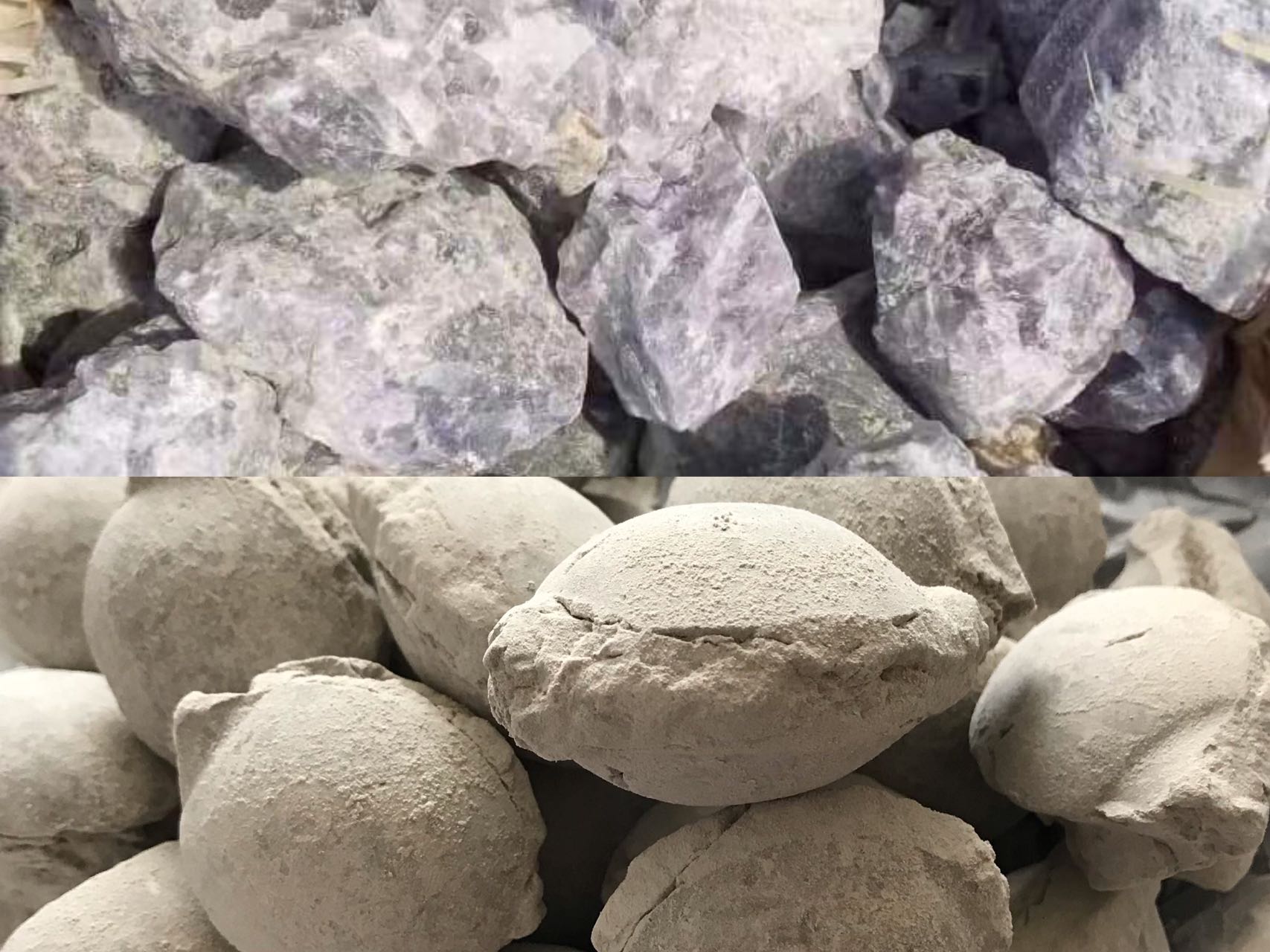

Fluorspar, also known as fluorite, is a valuable mineral used in a variety of industrial applications. High-grade metallurgical fluorspar is particularly sought after for its role in steelmaking. When talking about fluorspar products, the difference between fluorspar blocks and fluorspar briquettes is often discussed, and how they affect the steel production process.

Fluorspar blocks are an essential additive in the steelmaking process. They play a vital role as furnace cleaning fluxes, ensuring effective removal of impurities and maintaining the integrity of the steel production environment. The use of fluorspar blocks is highly valued in the metallurgical industry because its natural composition does not contain any chemical additives. This natural ore is widely favored for its ability to enhance the steelmaking process without introducing unwanted chemical elements.

Fluorite briquettes are made by adding chemical reagents to fluorite powder. While this process may seem beneficial, it can have adverse effects on steel smelting. The introduction of chemical reagents in the production of fluorite briquettes will produce impurities and adverse reactions during the steelmaking process. As a result, the metallurgical industry generally discourages the use of fluorspar briquettes because of the potential risk they pose to the quality and purity of the steel produced.

When considering the choice of fluorspar blocks and fluorspar briquettes for steelmaking, the purity and effectiveness of the additive must be given priority. Fluorite blocks are a natural mineral that does not contain any chemical additives and provides a reliable and efficient solution for enhancing the steel production process. Their ability to act as furnace cleaning fluxes without introducing unwanted impurities makes them the first choice for metallurgical applications.

In contrast, using fluorspar briquettes requires adding chemical reagents to fluorspar powder, which brings potential risks to steel smelting. The introduction of chemical elements during the production of fluorspar briquettes may have adverse effects, affecting the quality and purity of the steel and ultimately the entire steelmaking process. Therefore, bulk metallurgical grade high-grade fluorspar remains the first choice for steelmaking applications.

To sum up, the difference between fluorspar blocks and fluorspar briquettes lies in their composition and impact on the steel production process. Although fluorspar blocks are a natural and effective steelmaking additive, fluorspar briquettes produced with chemical reagents pose potential risks to steel smelting. When quality and purity in steel production are primary considerations, choosing bulk metallurgical grade high-grade fluorspar is the best solution for the metallurgical industry.

Post time: Mar-26-2024